Product Description:

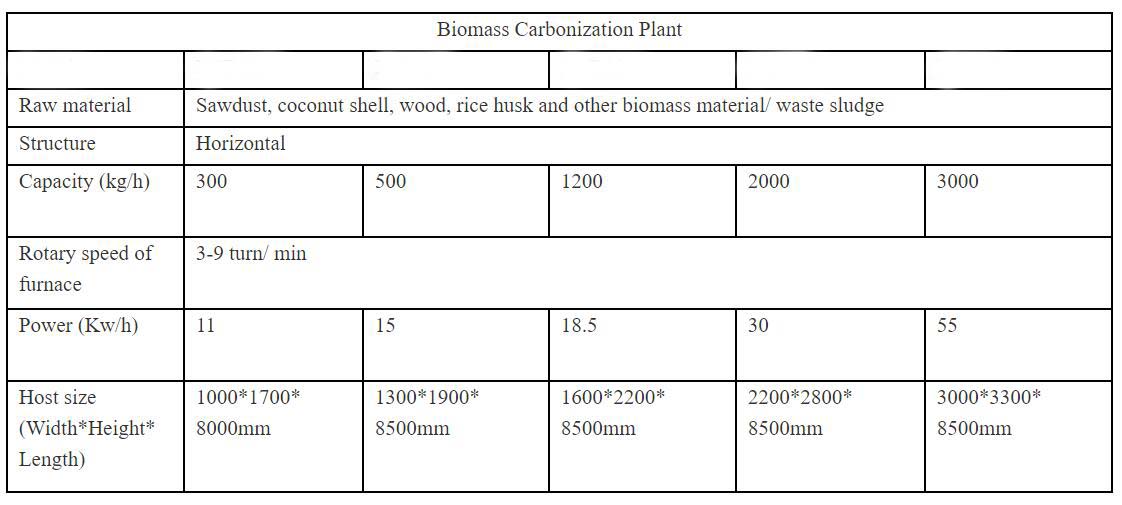

1. Model: TH-03, TH-05 , TH-12, TH-20, TH-30

2. 24-hour capacity: 300kg/h, 500kg/h, 1200kg/h, 2000kg/h, 3000kg/h

3. Combustible waste can be reduced in size by more than 95%.

4. By-product of garbage carbonization process "artificial carbon" fixed carbon content is high (about 90%)

5. Partial carbonization of rubbish can be activated very scalable (can activate up to 75%).

6. EU standard emmission

7. Energy recycling and reusing design to save fuel

The Raw Materials for the charcoal carbonization furance:

Sawdust, Rice Hull, weeds and shells (coconut shell), straw, such as biogas residue biomass, municipal solid waste, sludge, paper making Slag, and other organic produce, etc.

End Product after the carbonization process:

After the process which includes high temperature pyrolysis, volatile gas, sulfur emission, carbon enrichment of garbage disposal technology, The end product we get is artificial carbon.

Specification:

Carbonization biomass is a waste treatment technology that uses biomass (wood chips, wood, coconut shells, rice husks, stalks of plants, shells, and sewage sludge)) as raw material, "high temperature pyrolysis gas volatile, sulfur emission, carbon enrichment" process "artificial carbon" and by-product. Biomass in the absence of air oxidation, such as situations of incomplete thermal decomposition to produce carbon and other products.

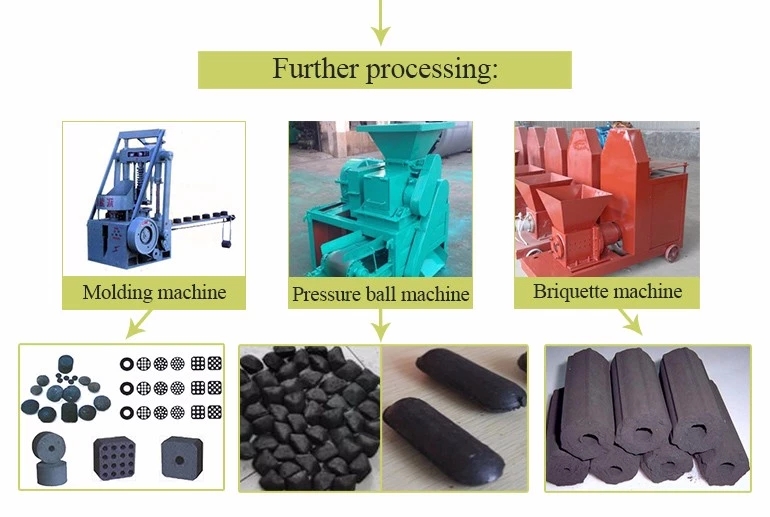

Further process matched machines:

We can also supply Crush machine, molding machine, pressure ball machine, and briquette machine to meet your requirements. Any other needs, please contact us, we can offer you a most suitable solution according your demands.

Technical Data:

Equipment Feature:

1. This machine adopts a two - tier structure design of multi - channel, mainly consist of the drying host, the host , the carbide machine. and Other accessories. Besides, It consists of transmission parts, part of the rack, drying part, the flash layer carburizing, feeding and bulk parts, materials and cooling, gas re - burning, the Water Curtain dust removal, parts of gasifier and related piping and other devices. And according to user needs (custom component ), we could add the Walking mobile parts.

2. First, The Structural Design of the upper and lower layers make the lower parts fully touch with the hot air Source. So we improve the heat utilization efficiency from the source based on the first step.

Second, for our second lever device, using the waste flue gas heating from carbide to flash the materials, On the basis of the original, we improve the Improved thermal efficiency again.

Third, the optimization of multi - channel integrated design, including the hot air source (gasification furnace or stove) collected exhaust channel, the outer carbide fission heat collecting channel, the inner layer of flash steam collecting channel, burning waste gas collecting channels, make it possible for improving the utilization ratio of heating for the third time. The three optimum utilization of the hot air, which eventually drops the temperature of exhaust below 100°C. Signed by the relevant departments, the thermal efficiency is up to 85% devices, Our user of Elias hemp plant in Xinjiang who named the machine " Flax bars carbonation artifact.

Service:

1. Delivery time- It will be 30 days after we receive the deposit.

2. 24 hours online service.

3. One year warranty from the date of receiving. The warranty equipment within warranty time, facilities failure is freely repaired or replaced by our company.

4. According to users’ needs, after deliver equipment, we can send technical personnel to train operation, maintenance.

5. After the expiration, seller provide spare parts at cost price.

6. Seller provide free lifetime technical services.

7. Whether it is within the warranty period, once receiving a notification service, maintenance personnel to reach the user site in 48 hours.

8. Regular visits, listen to users’ comments and suggestions on the service quality and product quality.

Contact: Peter Chang

Phone: +86-13933858520

Tel: +86-13933858520

Email: manager@thunder-international.com

Add: No.606, YSG Office Building, West Road of Zhonghuan, Airport Economic Zone, Tianjin, China

We chat