Mgo sanding board (also called Magnesium Oxide sanded board, sanded Mgo board) is a multi-functional fire-resistant sheet material with high quality. The Sanded Mgo board surface is by sanded treatment, which made it more smooth and flat, the thickness is more accurate, is suitable for direct decoration and lamination with PVC film, HPL sheet, paper, etc.

-Material: MgO+MgCl2 or MgO+MgSO4 +others

-Surface: One side smooth, the other side with sanding treatment

-Color: White & Grey

Features:

Mgo board contributes to a more efficient, profitable, environment-friendly and health-friendly construction production. It has excellent properties for fire proof, sound resistance, impact resistance and without health-hazardous raw materials.

-Fire resistant (Class A1) building material

-Lighter, more flexible and stable than traditional sheeting systems

-Time and material saving - dramatically reducing construction costs

-Environment friendly, applying a sustainable production process with reduced CO2 footprint

-Ideal for time, safety and health sensitive construction applications

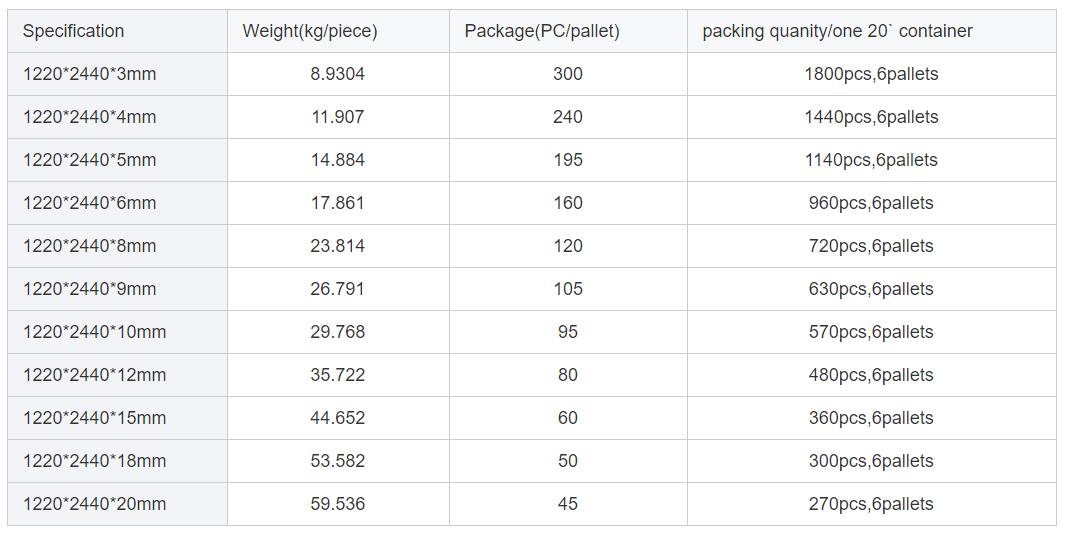

Specification:

Thickness: 3mm-20mm

Standard size: 1220X2440mm, 1200x2400mm, (other sizes can be ordered according to the customer's request)

Application:

Magnesium Oxide board has been used primarily as fireproof materials for walls and ceilings in office buildings, apartment complexes, residential constructions, hotels, theatres, restaurants, railway stations, airports, scientific research institutions, schools, hospitals, and stadiums. Some patterned products have been used as decorative boards. It also can be used as an interlayer for building, movable partitions, sound-absorbing structures, sound insulation structures, heat insulation and preservation structures, sign boards, fireproof partition walls, low fencing partitions, fireproof pipeline, fireproof doors, cornice baffle boards, public restroom dividers, baseboards, truck cabinets and billboards etc

-In heat insulation as an exterior side coating

-In partition wall systems in interior locations (6-2mm)

-In construction of suspended ceilings (6-10mm)

-Raised floor construction (14mm and above)

-Used as roof sheathing panels (12-16mm)

-In construction of interior and exterior walls, floor and ceiling of light steel prefabricate buildings

-Fire protection of heavy steel buildings

-In furniture manufacturing (fireproof door, counter, cupboard, etc)

Inspection and delivery:

-We are committed to pursuing customer satisfaction by delivering world-class quality products and services through continuous improvements and innovations.

-Our quality management system includes Pre-Production Inspection for raw materials, In-Process Quality Control, Container Loading Supervision (Pre-Shipment Inspection).

-We have a strong system for traceability and immediate status control to make our production efficient, providing feedback to the product development process.

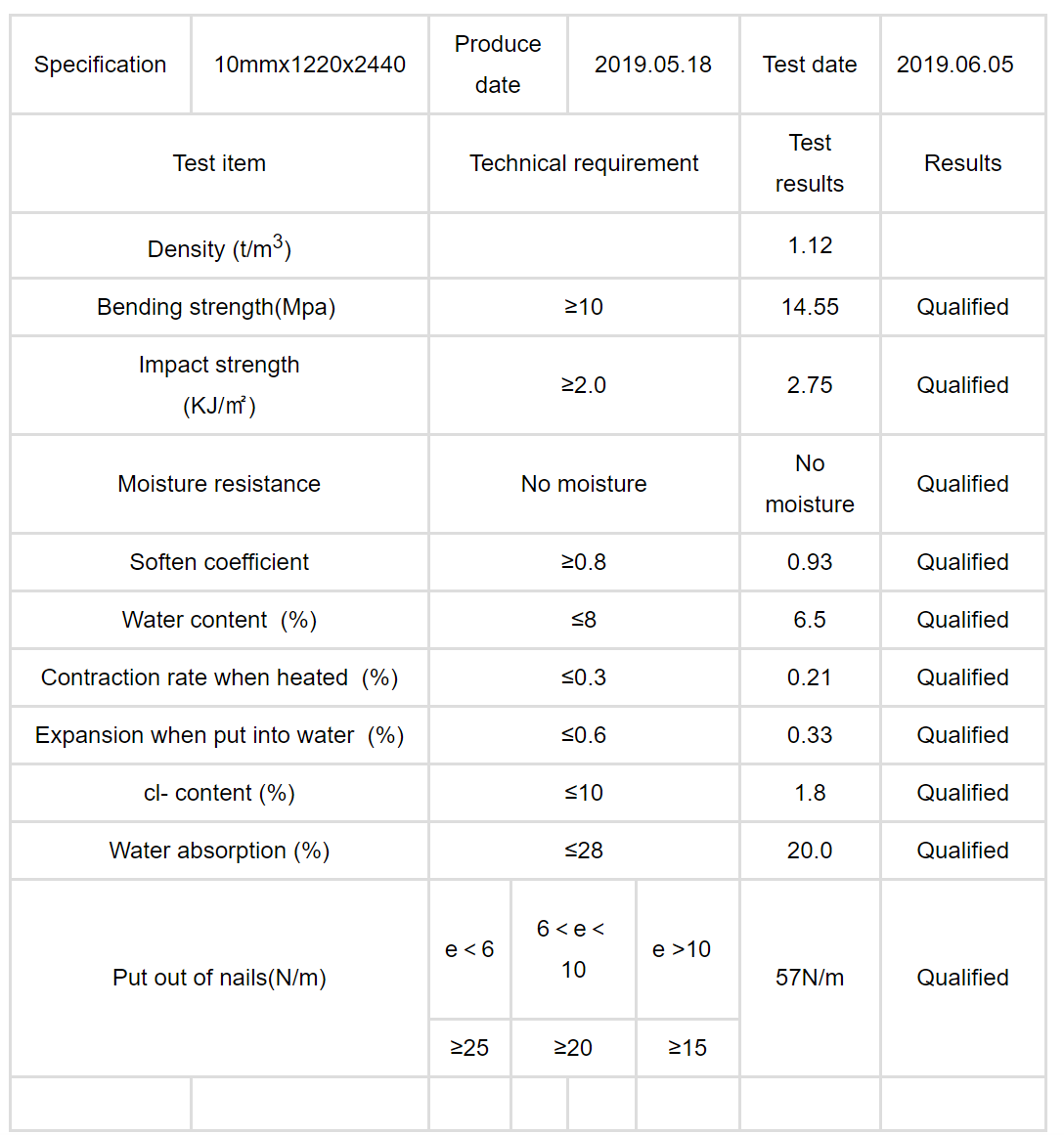

Mgo board test report:

Contact: Peter Chang

Phone: +86-13933858520

Tel: +86-13933858520

Email: manager@thunder-international.com

Add: No.606, YSG Office Building, West Road of Zhonghuan, Airport Economic Zone, Tianjin, China

We chat